CLAAS combine harvesters | DOMINATOR 130. How you benefit.

- MULTICROP concave for fast changeover between grain and maize

- The highly effective CLAAS Intensive Separation System

- Advanced technology for use in all crop types

- 3D-cleaning system for slopes up to 20%

- Made in Germany: as always, the DOMINATOR 130 is built at our main plant in Harsewinkel and impresses with its reliable, rugged technology

8. Threshing system

9. Cutterbar with working widths of 4.27 m and 4.57 m

10. Crop lifters

11. Dividers

12. Mechanical reel drive

13. Hydraulic reversing

| Drum width | No. of straw walkers | Grain tank | Engine | Maximum output (ECE R 120) | |

| mm | l | kW/hp | |||

| DOMINATOR 130 | 1060 | 4 | 3200 | Perkins 1106D-70 TA | 112 (152) |

Makes the most of the crop.

The DOMINATOR is equipped with the CLAAS threshing unit, which has proven its worth over and over again in the field. Clean threshing, protective grain handling, optimal deawning and high separation efficiency deliver the excellent grain quality expected in the market today.

3D turns slopes into level ground.

In addition, the AVERO is equipped with the impressive features of the 3D-cleaning system developed by CLAAS:

- Dynamic side slope levelling via active control of the upper sieve

- Completely consistent performance on side slopes up to 20%

- No wear - completely maintenance free

- Fast, simple retrofitting

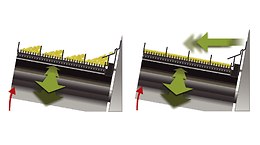

Intensive separation.

The high efficiency of CLAAS intensive separation systems has also impressed users for years. A controlled agitator tine above each of the straw walkers digs deep into the straw, loosening and fluffing it and so increasing the separation performance.

Top chopping.

The straw walker design ensures optimum straw quality for baling. And if there is no need to harvest the straw, you can simply use the chopper, whose 40 blades and speed of 3300 rpm ensure that it is chopped short and distributed evenly over the entire width of the cutterbar.